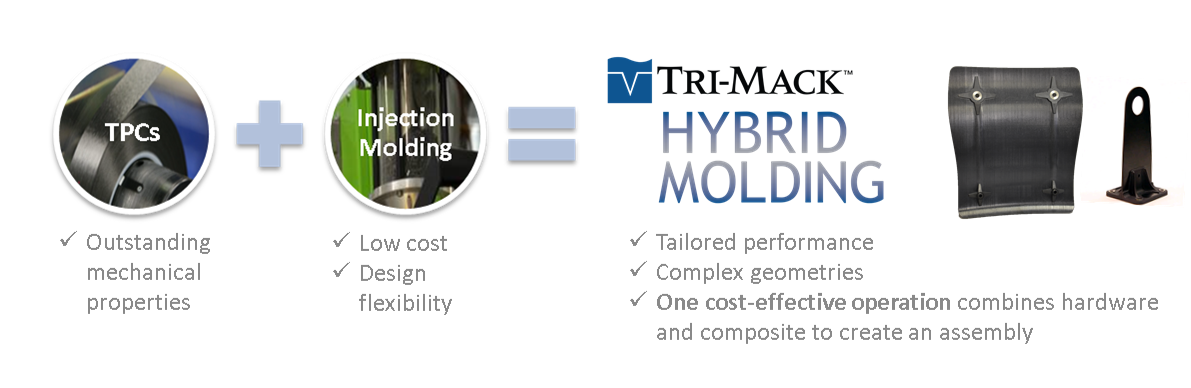

Tri-Mack’s latest hybrid molding processes combine thermoplastic composites with injection molding to capture the key advantages of both.

Based on a recent comparative study on bond strength, our hybrid molding bond is twice as strong as industry standard adhesive!

Improve your product's performance...

- Increased strength wih UD thermoplastic composites

- Improved design flexibility with over-molded geometry

- Save on weight

...While saving money.

- Create complex assemblies straight from the mold

- Shorter cycle times than thermoset composites and metals

- Reduced part counts

- Fully automated robotic injection molding cell

- In-mold forming and assembly

- Reduced tooling costs and process steps

- Automation ensures high-quality, low cost components

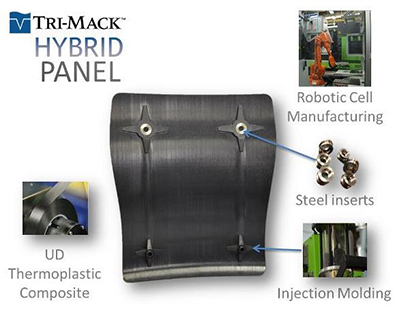

Watch the hybrid panel process.

- Manufacturing of complex designs

- Victrex AE250 composite enables overmolding with Victrex PEEK

- One cost effective operation combines hardware and composite to create an assembly

Watch the hybrid bracket process.

Tom Kneath discusses the benefits.

Watch Tri-Mack's automated one-step hybrid molding process!

How strong is the bond? Watch the video below!