Tri-Mack uses automated processes to produce parts from two different forms of engineering thermoplastics. Traditional thermoplastics can be injection molded, compression molded and machined from extruded shapes. Thermoplastic composites are laid up using fiber reinforced tape and fabric, consolidated then thermoformed.

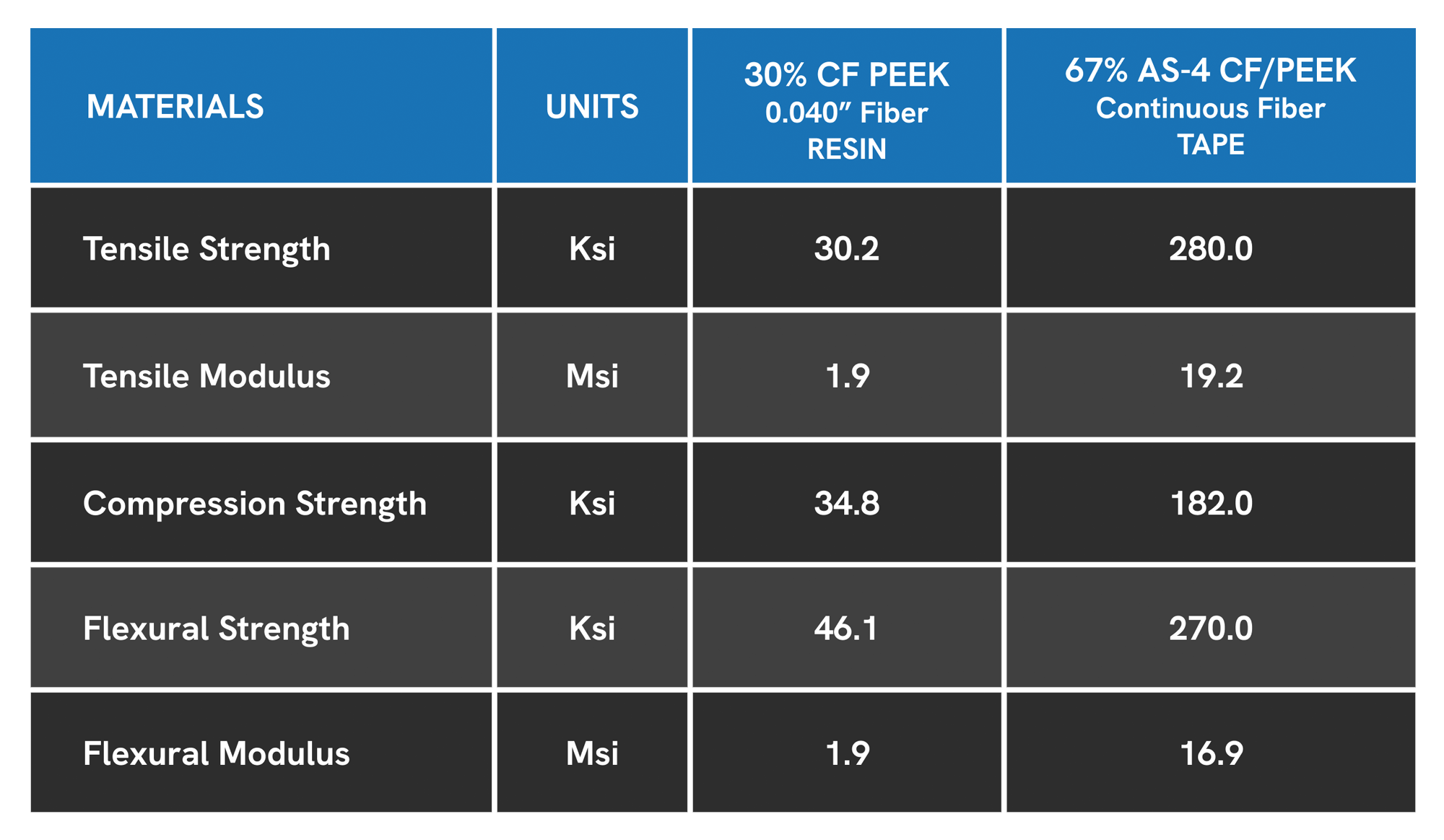

Thermoplastic composites are high fiber content materials with exceptional mechanical properties. Tri-Mack works with unidirectional or woven carbon, glass and aramid fibers in a polymer matrix such as PEEK, PEI, PPS, and PA. These materials are processed into sheets, thermoformed into shapes or combined with injection molding to produce hybrids.

Components produced using continuous fiber reinforced thermoplastics are very stiff and perform well in high-vibration environments. With their outstanding mechanical performance, thermoplastic composites offer significant weight savings when replacing metallic components.